Demand Driven MRP is a manufacturing strategy of sudden lead time compression maintained in a healthy production environment. It allows gaining customer service levels, lower cost in expedite and keeping right levels of inventory.

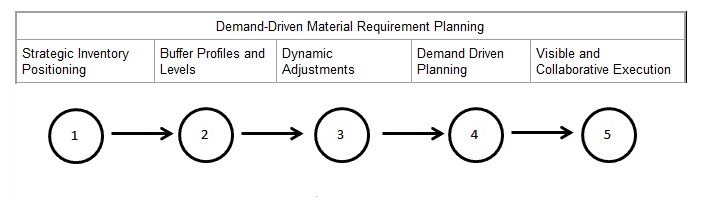

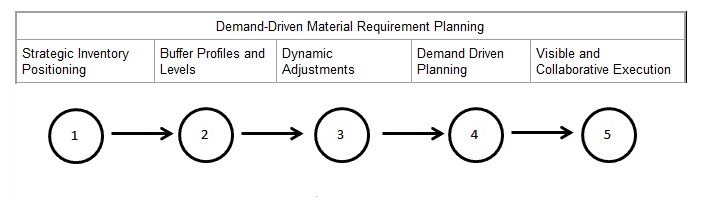

DDMRP consists of five main components:

Strategic Inventory Positioning is the first step in DDMRP implementation. Main step in the process is to identify which parts are a candidate in defining as buffered parts. Component identification includes:

Primary focus is to evaluate shared components which exists in many structures with a considerable unprotected lead time. It is necessary to identify whether the parts are potential items to be stocked, in order to reduce lead time or stock level of the parent parts.

Once defining the strategic decoupling points, it is necessary to set some rules on how these decoupling points are managed further. Buffer profiles include some generic group of characteristics of parts. Apart from that, lead time categories and variability categories help to classify different parts into different categories considering their unprotected lead time and analyzing their supply and demand situation. With the help of these attributes buffer levels can be established. Buffer levels are color coded buffer zones, which are used in the planning phase to manage inventory levels of buffered or lead time decoupled component parts.

Buffer zones are calculated based on the following factors:

There are in total five buffer zones:

The black zone represents stock out, while the blue zone represents any value above the green zone. The remaining buffer zones are determined as below. If any adjustments are applicable then they will affect the buffer zone calculations as well.

Yellow zone is calculated as:

Green zone, consider the largest value of the following:

Red zone, calculated as the sum of the Red Base and the Red Safety:

E.g., with the following input:

Calculations would be:

Over time conditions placed on the buffered parts might change. I.e., introduction of new suppliers or components, changes in the manufacturing process and/or methods. To handle these new conditions the buffer levels might have to be adjusted. Mainly there are four types of adjustments:

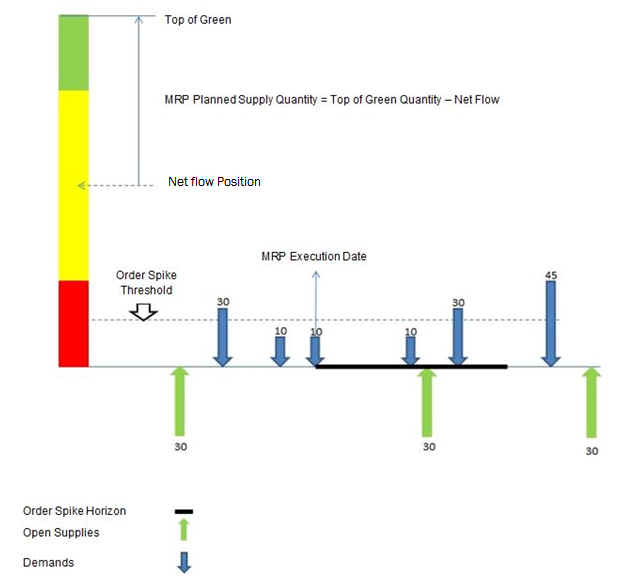

When buffer levels and buffer zones are established MRP will consider the buffered parts for planning. Once MRP is performed, MRP planned supply is created without considering the demands that fall in future but considering open supplies, on hand quantitites, demands due today, past due demands and qualified order spikes. Qualified order spikes are demands which fall within order spike horizon and which equals or exceeds the order spike threshold. Considering all these parameters Net Flow Position can be calculated as:

Net Flow Position = On Hand Quantity + Open Supplies - Past Due Demands - Demands Due Today - Qualified Order Spikes

Mainly buffers are divided in Red Zone, Yellow Zone and Green Zone. If the net flow position derived according to the above equation falls below the green zone, MRP creates a plan supply order with the following quantitiy:

MRP Plan Supply Quantity = Top of Green Zone Quantity - Net Flow Position (MRP Plan Supply Quantity will be further subjected to Lot sizing as well)

Demands will only be exploded to the lower component from parent when MRP plan supply exists, also demands will only be exploded according to the MRP plan supply quantity.

E.g., a specific part has following zones and all the Demands and Supplies situation as below:

Calculations:

Planned supplies are reviewed and converted to open supply orders based on the planning priority, which is calculated as Net Flow Quantity / Top of Green. Demand driven planning ends when planned supply orders have been converted to open supply orders.

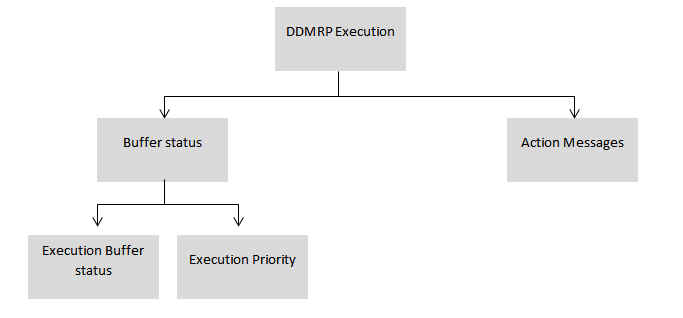

DDMRP also facilitate identifying priorities of order management. Buffered parts can be categorized according to the MRP on hand buffer status. These statuses are categorized in to five categories Blue, Green, Yellow Alert, Red Alert and Black Alert. Depending on status open supply orders can be further executed by analyzing the on hand status.

Apart from that, percentage of on hand over total red zone which is presented as Execution Priority is provided to identify priorities when executing orders. It shows the severity of decreases of on hand quantities.

Supply orders execution priorities can be identified with the help of below elements:

This is how the Execution Buffer Status categories are set up in the application:

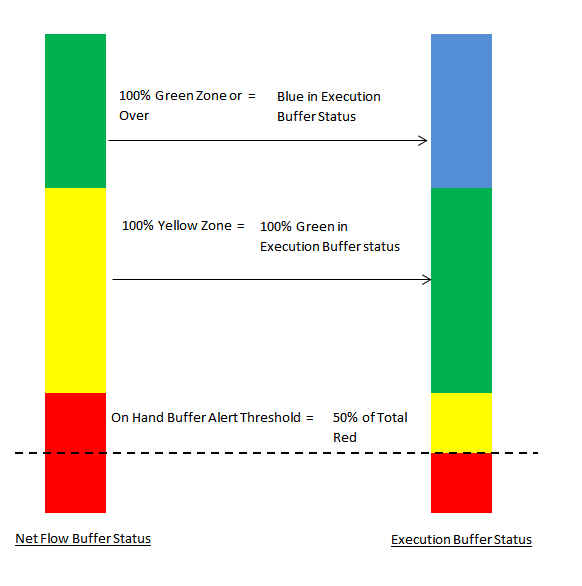

On Hand Buffer Alert Threshold is defined as a percentage of Total Red Zone. Each Planning Zone or the Net Flow Buffer Zones can be converted to Execution Buffer Status categories.

For eg: If On Hand Buffer Alert Threshold = 50% of Total Red Zone then,

0% - 50% of Red Zone of Net Flow Buffer Status = Red Alert in Execution Buffer Status

51% - 100% of Red Zone of Net Flow Buffer Status = Yellow Alert in Execution Buffer Status

0% - 100% of Yellow Zone of Net Flow Buffer Status = Green in Execution Buffer Status

0% - 100% of Green Zone and above in Net Flow Buffer Status = Blue in Execution Buffer Status

Action Messages:

| Action Message | Follow up |

| No Demand within unprotected lead time | This message is displayed when no demand exists within the unprotected lead time. This can be useful if the on hand buffer status is in the red zone. Since no demand exists these parts are low prioritized. |

| Reschedule Supply order(s) | This message is displayed for buffered parts which have Execution Buffer Status in the Black Alert or Red Alert and Net Flow Buffer Status in the Green Zone or Blue Zone. It means that the part has a negative value sometime in the projected on hand. This condition is only evaluated up to unprotected lead time ahead from MRP execution date. Late order(s) need to be rescheduled. |

| Late Order(s) - Buffered Part | This message is displayed if Execution Buffer Status is in the Black Alert, Red Alert or Yellow Alert, projected on hand is positive within the unprotected lead time, and Net Flow Buffer Status in the Green Zone or Blue Zone. Informational message stating that on hand buffer status is in trouble, but should reach a positive projected on hand without any stock outs, given the current order status. |

| Buffer zones not defined | This message is displayed when running MRP before properly defining buffer zones. |

| PMRP does not support planning method H, part planned as A | This message is displayed if trying to run DDMRP for PMRP. |

Note: Lobby Elements are provided both for Net Flow Buffer Status and Execution Buffer Status.