Outside Operations

Introduction

Outside operations in IFS Applications is provided through manufacturing operations

related to an outside work center. The outside work center is a work center that

is not owned by the company at which the manufacturing occurs. The outside

work center is generally considered to be a location outside the site at which the

manufacturing occurs, but can also be a supplier's work center

located within the site. The material sent to and received from the supplier is

tracked by an outside operation item registered on the outside operation. When the

outside operation is released, a purchase requisition or order is created for

the outside operation item.

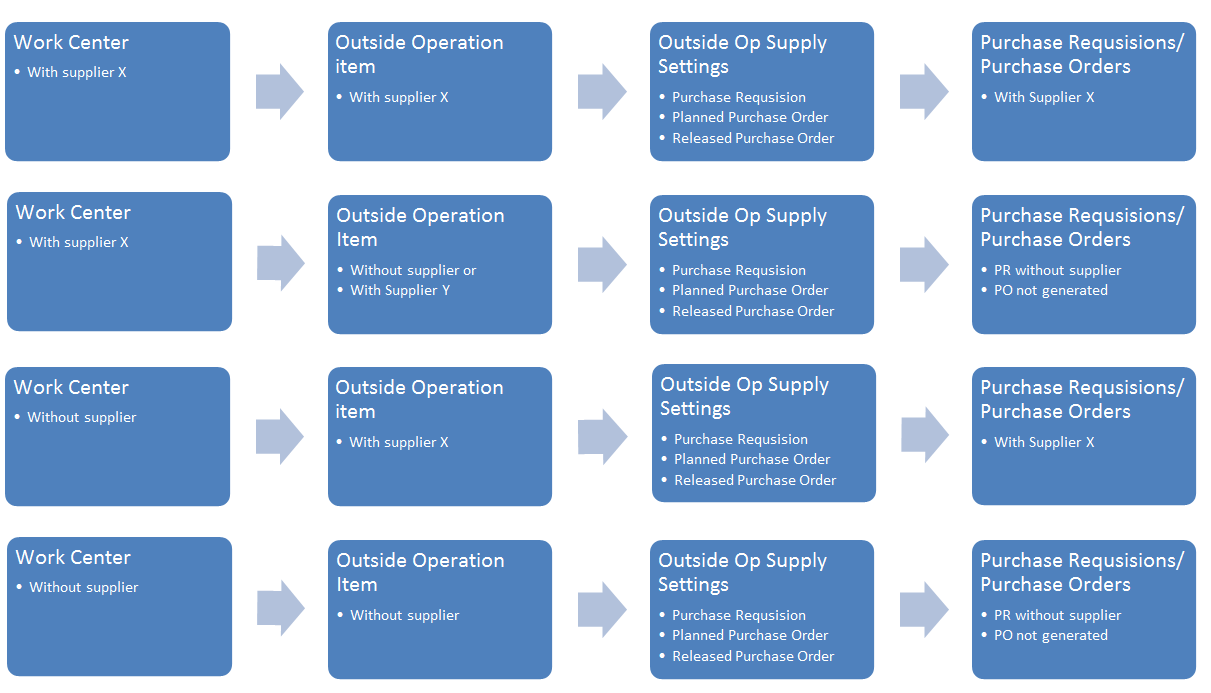

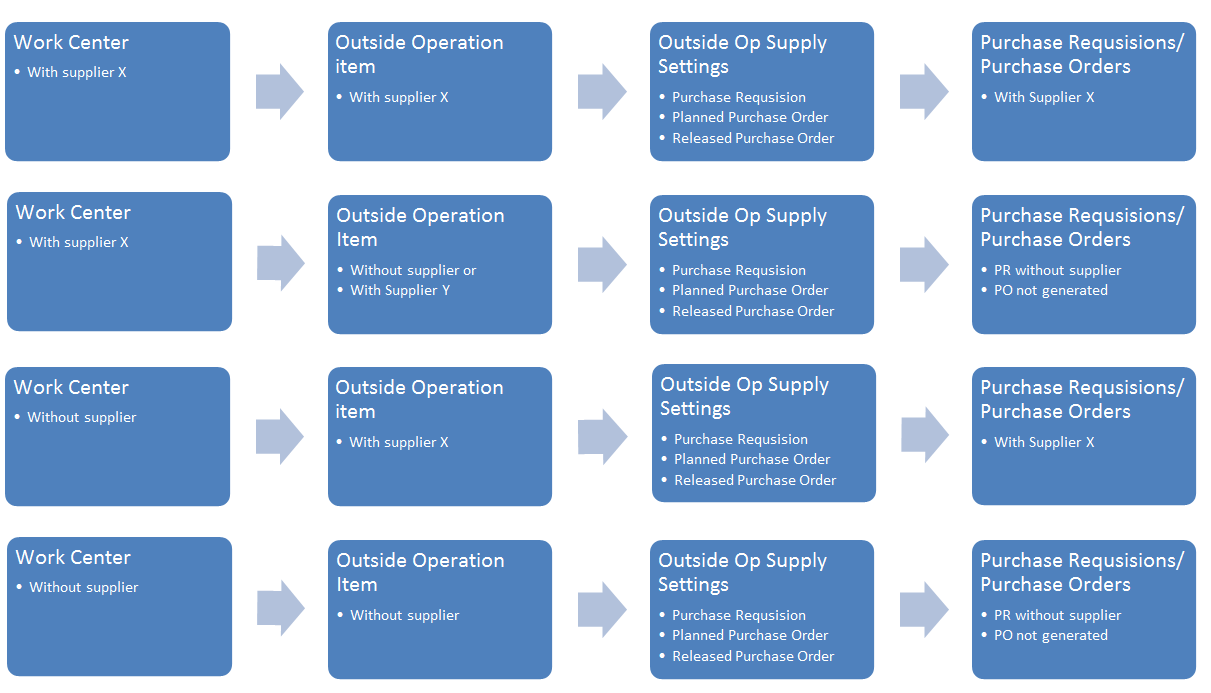

Outside Work Center and Outside Operation Item

The outside work center is defined in the

Work Center window by setting the Work Center Code to Outside Work

Center. A supplier can be related to an outside work center. The supplier on

the outside work center is used by default when creating outside operation items. Also,

this supplier will be used instead of the default supplier of the purchase part if

the outside operation item part is registered for that supplier, when generating

purchase requisitions or orders.

The outside operation item is used as a proxy for the material

to be moved to and from the supplier. The outside operation item is a non-inventory

purchase part usually with a supplier of the purchase part corresponding to the

outside operations supplier. The outside operation item is entered in the

Purchase

Part and

Supplier for Purchase Part windows. Material movement through inventory locations

to and from the supplier will not be recorded. The WIP account is adjusted, and the cost

of the outside operation is accounted for with the reporting of the WIP sent to the

supplier and the reporting of the arrival of the outside operation item from the

supplier. It is the estimated WIP amount that is used when calculating WIP for outside operations.

Outside Operation Supply Settings

An outside operation supply type setting on the shop order

operation determines how the outside operation will be released. There are three

settings for the outside operation supply type. They are:

-

Purchase Requisition – A purchase requisition will be

created for the outside operation item when the outside operation is

released or when the shop order is released. The WIP must be reported as

shipped to the supplier, the requisition must be converted to an order and

then released before reporting the arrival of the purchase order.

-

Planned Purchase Order – A

planned purchase order will be created for the outside operation item when the outside operation is released

or when the shop order is released.

The WIP must be

reported as shipped to the supplier, and the purchase order must be released

before reporting the arrival of the purchase order.

-

Released Purchase Order – A

released purchase order will be created for the outside operation item on the

outside operation when the outside operation is released or when the shop

order is released.

The WIP must be

reported as shipped to the supplier before reporting the arrival of the purchase

order.

This matrix is valid for handling shop orders with outside operations. It is not possible to save an outside operation in the Routing,

Routing Template, or Standard Operation with one supplier on the work center and a different one on the outside operation item.

Work in Progress reporting for Outside Operations

The WIP must be reported as shipped to the supplier,

after the

outside operation is released and before the outside operation item purchase order

arrival can be reported. The WIP shipped to the supplier can be reported in the

Report Shop Order Operation or the

Report Work Center Operation windows. The WIP shipped to the supplier can also be reported

by

using the outside operation backflushing.

Outside Operation Backflush

Outside operation backflush options can be used to automatically perform some steps in the outside operation reporting work flow.

The Ship WIP to Supplier step can be performed when reporting purchase order

line arrivals for outside operations. The Ship WIP to Supplier step and the

reporting of released purchase order line arrivals can be performed by registering

the completion of the outside operation in the

Report Shop Order Operation and

Receive Shop Order

windows. To backflush outside operations, the Outside

Operation Backflush option needs to be set before the operation has been

released. There are three settings for the Outside Operation Backflush

option. They are:

·

Disallowed – Automatic reporting of the WIP shipment to the supplier

and the purchase order arrival of the outside operation item is not allowed.

·

Ship WIP to Supplier – The ship WIP to supplier can be

automatically reported at purchase order receipt. If the sufficient

quantity of a preceding

operation has not been completely reported, or a sufficient inventory stock of

the component parts related to the outside operation does not exist, a

message will appear.

This setting is typically used when the outside

operation supplier is operating externally from the site.

·

Purchase Order Arrival – The ship WIP to supplier can be automatically

reported at purchase order receipt, and the purchase order receipt can be

performed when reporting the outside operation. If the sufficient

quantity of a preceding

operation has not been completely reported, or a sufficient inventory stock of

the component parts related to the outside operation does not exist, a

message will appear.

This setting is typically used when the outside

operation supplier is operating on site, or to simplify reporting for the

preceding outside operations on a routing with sequential outside operations.

Send to Next Supplier

The Send to Next Supplier option for shop order outside operations is used to control whether or not outside operation material should go directly from the supplier of one outside operation to the supplier for the next outside operation when there exists two, or more, consecutive outside operations.

Example where the Send to Next Supplier option is used:

| Operation No |

Type of Operation |

Supplier |

Send To Next Supplier |

| 10 |

Internal |

- |

- |

| 20 |

Outside |

A |

Yes |

| 30 |

Outside |

B |

No |

| 40 |

Internal |

- |

- |

The outside operation material is sent to supplier A for operation 20. When supplier A has completed their work they send the material directly to supplier B.

When supplier B has finished their work they will send the material back to the site at which the manufacturing occurs

Note: Outside operation backflush will be used to automatically backflush the ship work in progress transactions (WIP) to supplier and the

purchase order arrival activities to report the preceding outside operations on a routing with sequential outside operations, if the Send to Next Supplier option has been

selected for the preceding outside operation. In the example above the missing WIP transactions for the purchase orders pegged to operation 20 and 30, and the purchase order arrival activities for the purchase order pegged to operation 20 will be backflushed when the purchase order arrival is reported for the purchase order pegged to operation 30.

Example where the Send to Next Supplier option is not used:

| Operation No |

Type of Operation |

Supplier |

Send To Next Supplier |

| 10 |

Internal |

- |

- |

| 20 |

Outside |

A |

No |

| 30 |

Outside |

B |

No |

| 40 |

Internal |

- |

- |

The outside operation material is sent to and received from the supplier A for operation 20 before the material is sent to and received from the supplier B for operation 30.

When supplier A for operation 20 has completed their work they will send the material back to the site at which the manufacturing occurs. They will not send the material directly to the supplier B of operation 30.

Document Text

Document texts connected to the purchasing documentation output type and added anywhere on

the manufacturing side of the outside operation workflow will automatically also be available on the purchasing side of the outside operation workflow by the following logic:

Standard Operation -> Routing Template Operation -> Routing Operation -> Shop Order Operation -> Purchase Requisition Line -> Purchase Order Line.

Example: If a document text is connected to a shop order outside operation it will automatically be available on the purchase requisition and purchase order.

For more details about document texts refer to the Document Data for Inventory and Distribution topic description

Document Attachments

Document Attachments added anywhere on the manufacturing side of the outside operation workflow will automatically be available, as read-only copies, on the purchasing

side of the outside operation workflow by the following logic:

Standard Operation -> Routing Template Operation -> Routing Operation -> Shop Order Operation -> Purchase Requisition Line -> Purchase Order Line.

Example: If a document is attached to a routing operation then a copy of the original document will be available on the shop order operation, the purchase requisition and the purchase order.

Delivery Note

It is possible to print an outside operation delivery note if a pegged purchase order exists for the shop order outside operation.

The delivery note is used to accompany the goods to the outside operation supplier, and lists a description and quantity of the goods delivered.

The outside operation delivery note always includes information such as:

- Part Number

- Quantity Delivered

- Shop Order Reference

- Purchase Order Reference

- Document Texts

- Delivery Address

- Supplier Address

Optionally it is also possible to include the following information in the delivery note.

- Operation Material Allocations

- Material Work Guidelines

- Operation Work Guidelines

Note: The supplier delivery and supplier document addresses, as defined on the purchase order, are used as delivery and supplier addresses in the delivery note.

Note: The content of the footer in the delivery note is defined by the following logic:

- If a document footer has been defined in the

Document Footer window, and been connected to the outside operation delivery note report, then this footer will be used.

- If no document footer has been defined, then the information in the Page Footing field in the Company/Invoice/General tab will be used as the footer in the delivery note report.

- If the Page Footing field has not been defined, then the document address defined in the purchase order header will be used in the delivery note report footer.

Cost of Outside Operation

When you calculate cost for a manufactured part which include an outside operation,

the cost for the operation is fetched from

Outside Operation Cost. The cost for an outside operation includes unit cost,

batch cost and overhead cost for those. When you calculate outside operation costs, both batch costs and the cost per unit are considered.

The cost per unit of an outisde operation is calculated as:

Outside operation cost = (Batch Cost/Standard Lot size) + Cost per unit

When a purchase order is created for the outside operation, the price for the outside operation part is fetched by the purchase price logic. (Agreement, Pricelist…..)

The shop order estimate cost for the outside operation first tries to fetch the cost from the

Outside Operation Cost and if the cost

is zero the cost is fetched from the primary purchase part supplier. Supplier connected with the outside workcenter will not be taken into consideration.

The shop order actual cost is the price from the purchase order line, if there are any differences when the invoice is matched the actual cost will be updated.

Over- and Under Delivery of Outside Operation

In the outside operation flow it happens that discrepancies occur between

what is shipped to the supplier and what is actually receipted. There are

three scenarios where it can be seen within IFS/Manufacturing;

- Return quantity is less than the shipped quantity, meaning that the

quantity is less than ordered when the arrival is reported.

- Supplier sends more produced material than what is shipped.

- Over delivery of an inside operation results with the following

outside operation returning a greater quantity than the lot size.

Under delivery of an outside operation can be handled by either closing the

shop order or by performing an inspection at the arrival. If

inspection management is used then you are allowed to register inspection

results with one of these options, scrap with no credit or scrap with

credit. This makes it possible to handle situations where the supplier should be invoiced

differently based on the agreed upon method on deviations. You can also adjust the

price manually when matching the invoice if the supplier needs to be paid

differently.

If you want a warning about an outside operation which over delivers, then

the over delivery performance check on purchase part should be selected. Over

delivery of an outside operation occurs when a supplier sends more produced

material than expected. If the supplier should be paid for the over

delivery then is this something that needs to be taken care of either by

manually adjusting the quantity on the purchase order or by taking actions when

processing the supplier invoice.

Over Delivery

Over Delivery of Preceding Inside Operation

If an inside operation that precedes an outside operation over delivers,

then is it possible to ship the operation quantity, not just the shop order lot

size.

Greater Quantity than Shipped

There is no limitation of the possible quantity to receive as an over delivery

from an outside operation. The value of the shipped WIP can never appear in

terms of negative amounts, zero is the lowest WIP value that can be represented

at the supplier. An over delivery appears as positive calculation variance

for shop order cost.

Partial Receipt from a Supplier

If the quantity shipped to an outside operation is less than full quantity

and the outside Rpt Level is set to Disallowed then is it not possible to

receive a quantity greater than the part quantity shipped. it is only possible

to over deliver an outside operation when quantity shipped is equal to or

greater than the operation quantity. This means that you cannot perform an over

delivery from the supplier for each shipment of the operation quantity,

just when executing the final receipt.

The workaround to accomplish over delivery when the part quantity shipped is

less than full quantity is to split the operation based on part quantity

shipped. This provides the option to over deliver since the operation quantity

then is equal to the part quantity shipped for one of the split operations.

To be noticed; if the outside Rpt Level is set to either Ship Wip to Supplier

or Purchase order Arrival then is the part quantity shipped always back flushed

so that a one to one relationship exists between the receipt and what is

shipped. Hence is the problem described above not an issue if selecting any of

these Outside Rpt Levels; i.e. the over delivery can only be performed at final

receipt.

Purchase Order and Invoice Matching

Purchase order and invoice matching is handled with the standard purchase

order functionality. This means that if an over delivery has impact on the

purchase order where the supplier invoice needs to be matched then it is something

that you must handle manually. No support exists for updating of released purchase

orders connected to an outside operation.

If a quantity is shipped to a supplier which is greater than the lot

size and if a purchase order exists in a higher status than Planned then

an information message will raise. This message contains information about the

differences which exists between the shipped quantity and the quantity defined for the

purchase order line used in the outside operation shipping process. If a

purchase requisition or a purchase order exists in status Planned then

the quantity will get updated automatically when shipping a quantity greater that the lot

size. In the scenario where no purchase requisition or purchase order is

connected to the outside operation where the shipping quantity greater that the lot

size to the supplier, then these objects are created based on the

shipped quantity instead of the lot size.

Under Delivery

Closing Shop Order with Tolerance

You can receive a quantity less than the lot size from a supplier when

registered purchase order arrivals. You can continue the

execution of the next operations and if no complementary deliveries can be

expected for the supplier then the shop order can be closed. This has the impact that the remaining WIP at

the supplier is cleared and instead appears as a negative shop order cost

variance. The shop order is further closed with a received quantity which is

less than the shop order lot size.

Inspect at Arrival

Supplier for purchase part provides the option to setup inspection management

with a receive case. If Receive into Arrival, Inspect at Arrival

is selected then is it possible to register inspection result with scrap as

option. If you select to scrap then there are two options,

- Scrap Credit

- Scrap No Credit

Depending on whether the supplier is paid or not for the scrap parts

only, these options be used,

Note: Scrap Credit means only credit for the work performed by the

supplier related to the quantity delivered. The outside operation cost when

scraping with credit is calculated based on the approved quantity; i.e. the purchase

price for the outside

operation multiplied with the approved quantity.

Purchase Order Matching and Invoicing

Purchase order and invoice matching is handled with the standard purchase

order functionality. This means that if an under delivery has impact on the

purchase order and/or the supplier invoice to be matched then this is something

that you must take care of in terms of manual actions. For instance; if it is

necessary to credit the supplier for the WIP connections of the scraped

parts then it is an issue which you need to deal manually when matching

the supplier invoice.

Receive Shop Order at Purchase Order arrival, if outside operation is the last operation

If the last operation on a shop order is an outside

operation, it is possible to receive the whole shop order at the time of the

purchase order arrival. This functionality is valid if the Receive

into Inventory on Last operation check box is selected at the used outside Work Center.

Receive case Receive into arrival

When the receive case is Receive into arrival,

Receive Shop Order dialog box will open up when registering the Purchase Order

Arrival. It is possible to change the location and the quantity in the Receive Shop Order dialog box and when doing the confirmation with clicking ok, the shop order gets received.

If the material is tracked in any way, the different dialog boxes for receiving shop

order with tracked material will be opened directly after clicking OK in the

Receive Shop Order dialog box.

If multiple lines are selected for doing the Register

Purchase Order Arrival, single Receive Shop Order dialog boxes for tracked

material will get opened one after the other.

Receive case Receive into arrival, Inspect at arrival

When the receive case is set to Receive into arrival or

Inspect at arrival, Receive Shop Order dialog box will open up when doing the

Purchase Order Arrival, and after completing the Inspections.