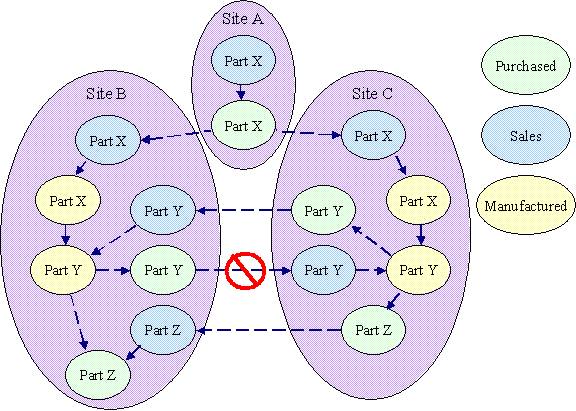

The multi-site planning feature plans a number of sites together as an internal supply chain. Internal supply chain execution is handled through distribution orders, which is a streamlined form of inter-site orders. The multi-site part structure expands upon planning features of a single site bill-of-material (BOM), to provide the information necessary for multi-site planning. The supplier part records for the parts distributed between a site and another internal supplier site define the connections. The multi-site planning connection is defined in the Supplier for Purchase Part window.

Multi-site planning can be performed only if the planning networks have been defined.

The multi-site planned parts definition is different from the planning network

definitions. Therefore, planning networks do not restrict multi-site part

definitions. When multi-site planning is performed for a planning network, only

the subsets of the multi-site part structure in the planning network are

planned. Distribution orders will be generated

by multi-site planning systems for internally sourced parts.

The supply parts can be sourced from a mix of manufacturing, internal sites, and

external suppliers. The multi-site planned indicator defines internally sourced

connections. These inventory parts must have the same part number in all the

different internal sites. For example, Site A receives part X from sites B and C

where it is manufactured. This relationship is defined by multi-site planned

internal suppliers for part X on site A, having a supplier split of 50% to the internal supplier for Site B and 50% to

the internal supplier for Site C. This

creates a multi-site part structure as follows.

When creating multi-site part connections, there will be a check to avoid creating loops in the multi-site part structures that are created. It is OK for one site to supply another with the same part. However, the relationships can only be in one direction. They cannot be bi-directional as shown in the example with Part Y.

Validation involves the following elements:

∑ A parent part cannot have a connection to itself, defined as a component part, in the multi-site part structure.

∑ Validations occur separately for different BOM types (e.g. Manufacturing, Repair, etc.), just as the loop validations in the current structure.

∑ Validations for multi-site structure loops are initiated from the following events:

o When adding or updating a structure record

o When adding a site to an inter-site partís sourcing options

o Changing the Material Requirements Planning method K (Blow Through Planning), T (Master Scheduling Level 0 Phantom), or O (Master Scheduling Level 0 Part)

The Multi-Site Planned check box on the Supplier for Purchased Part

indicates the part is Multi-Site Planned with the internal supplier. This

multi-site planned indicator defines the connections between internal sites

establishing a Multi-site Part Structure. The inventory part must exist at both

sites for multi-site planning. A multi-site planned part is considered by the

order planning and sourcing features such as Next Level Demand Calculations,

Material Requirements Planning, Master Scheduling, the Capability Check, and Costing. When an order proposal is created, distribution orders are used

to process the order for this part with the internal supplier. The Multi-Site

Planned check box is only enabled for internal suppliers, not external ones.

If the Multi-Site Planned check box is not selected, the planning processes stop

at this level, and do not pass the requirements to the internal supplier.

Multi-site cost rollups can be performed

on parts with supply sourcing rule definitions among internal sites. The

standard cost rollup procedures are used to perform the multi-site cost rollups.

The

multi-site cost rollup only rolls up costs among the sites for the 510 Inter-site

Material Cost bucket. All other costs are still calculated on a site-by-site

basis.